Hot air welding machine, also be called banner welding machine,PVC welding machine.It used to weld PVC, PE,TENT,Tarpaulin and other materials that can be hot melted.

LC3000C-new welding machine is the advanced one of LC3000C. It used the industry temperature control technology.Can control the temperature with in ±1℃. Equipped with red Laser pointing function. Also equipped with scalable handle. That is easier and more convenient when using it.

LC3000C-new also used the imported Switzerland Leister heat element.Its lifetime is longer compared with the original type.It can use 4-5 years and no need replace any parts of the machine.

Main technical Main technical of LC3000C PVC welding machine

Rated voltage: AC110-240V

Frequency: 50hz

Power: 1800w

Temperature range: 40-700degree

Temperature fluctuation:1degree

Speed scope: 2-8m/min

Welding thickness:0.2-1.8mm

Welding width: 3-4cm

Specifications :49*28.5*28cm

Weight: 15Kg

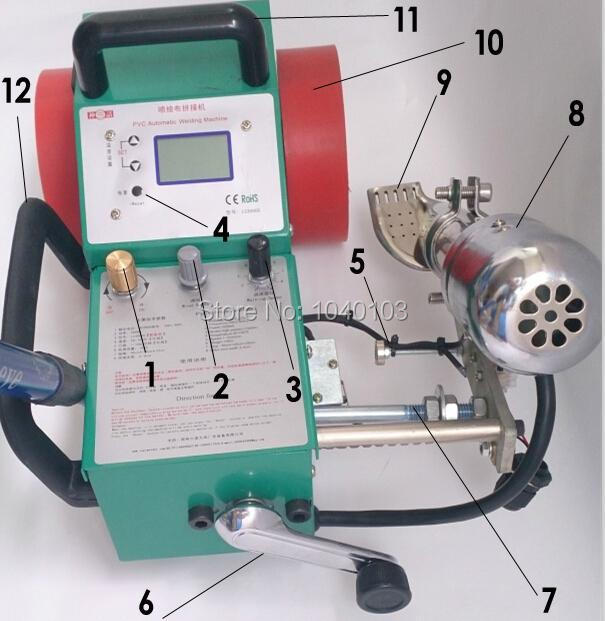

Parts of hot air welding machine

1.Temperature knob 2. Wind speed knob 3. Walking speed knob

4. Reset knob 5. Temperature feedback sensor 6.operation handle

7. Wing sheath 8.Heat gun 9. Nozzle 10.Press wheel 11.Carry handrail

12.Carry handrail 13.Actual temperature 14.Set temperature 15.Walking speed

16.Turn up temperature button 17.Turn down temperature button

Operation:

1.First, make the picture smooth and tight, take joiner to accurate (about 2-4cm),

fixed edges with tape or glue on the ground.

2.Set temperature:connect power, turn on the temperature knob (the golden knob)until it click,and then press(for up for down). In general, the temperature is between 350-400degree,Or to know it the temperature is ok,we can taking some waste banners to aligned nozzle to test, If

it can be melted immediately, This temperature is the one you need and to set.if not strong just increase

temperature,if too hot,reduce temperature.check photo below:

3.Set wind speed:in general,we put wind speed to the largest.so just put wind speed to the Maximum is ok.

4.Set walking speed:Then turn on waling knob to adjust the speed, generally marked on the knob points to

the location between 3 from 4.

5.Start welding:when actual temperature of the display screen reaches temperature that you set, we can begin

to weld.put operation handrail(at end of the machine)to left,machine begin to work automatically.

At begin of weld,we should use one hand to take one banner up,then put nozzle between two banners,

6.During welding,let hot air nozzle between two overlap pieces. And be make sure hot air nozzle and Rubber wheel walk in straight line.if not,please adjust by hand.check photo:

7.Finish welding:turn the walking handrail to the right ,machine stop walk,then turn off the yellow button(temperature knob),but before cut off the power,please wait until actual temperature below 50 degree,then we can

cut of the main power,or it would be damage heat system.

8. Do nott use it in rainy day,the workplace should be dry, flat and safety of fire.

The machine should have technical person to operate, it is forbid that someone use it without specific knowledge.

Working voltage:110V220V. Strictly prohibited without permission disassemble,you should be responsible the result

yourself.

Please pay attention:In order to keep heat element,we add Automatic Dormancy function,it means if not using

welder over 10 minutes,machine would be enter dormancy state.if want it reback to work,just press the Reset

button or put the operation handle to right is ok,but it needs 1 minute to raise the temperature,so we need to wait.

Tips:For first user,we can use waste banner to test and find proper temperature,we can do like this:take a small

banner close the nozzle,if the banner hot melt quickly,it means,the temperature is OK,it not strong or burnt,we

can increase or reduce temperature.we can also write down the temperature for this thickness of banner as sample.

in next welding,based on this temperature.we just need to increase or reduce the temperature depends on thickness

of banners.