Leopard A680 High speed, Super-wide UV Inkjet Printer:

A680 High speed, Super-wide UV Inkjet

Printer

Leopard A680

roll to roll high speed, super wide-format printer build a new beacon for

wide-format roll to roll UV Inkjet output by perfectly combining the printing

quality of point-of-purchase(POP) and the high-speed output of outdoor

large-format billboard. Leopard A680 UV large-format printer ensures digital

print company to make quick and efficient commercial promotion applications,

including exhibition graphics, digital textile, billboard signage and

commercial graphics. Adaptation of ultraviolet proof glass on the machine

protects the operator safely and ensure environment-frienly. Leopard A680

significantly extend your printing capacities and the range of application that

you can provide, boost your business grows by differentiating yourself from

other competitors.

Environment

protecting, high precision, and high productivity

◆Up to

5000mm with unlimited printing image length

◆360dpi high resolution, high speed industrial printheads makes

printing output quality outstanding with 1440dpi resolution.

◆By use of high precision, mute linear guide rail, you will enjoy the

quiet and wonderful printing process environment.

◆The 4 large diameter rubber rollers reduce the deflection and lead

the material moving more smoothly and prevent it from deviating. It protects

printed job and more suitable for large quantities of high speed printing.

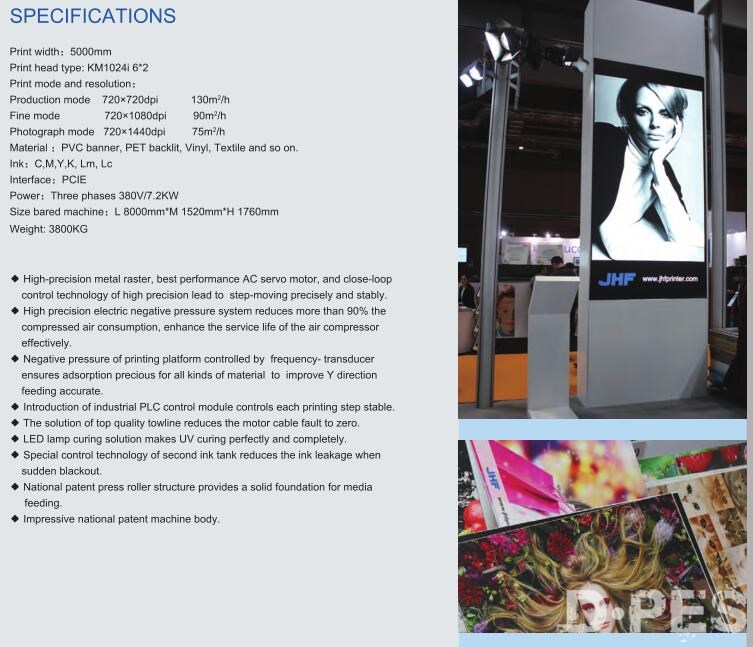

Specifications

Print width:5000mm

Print head type: KM1024i 6*2

Print mode and resolution:

Production mode 720×720dpi 130m2/h

Fine mode 720×1080dpi 90m2/h

Photograph mode 720×1440dpi 75m2/h

Material :PVC banner, PET

backlit, Vinyl, Textile and so on.

Ink:C,M,Y,K, Lm, Lc

Interface:PCIE

Power:Three phases

380V/9KW

Size bared machine:L8000mm*M

1520mm*H 1760mm

Weight: 3800KG

◆High precision metal laser, best performance AC servo motor, and

close-loop control technology of high precision lead to step-moving precisely

and stably.

◆High precision electric negative pressure system reduces more than

90% the compressed air consumption, enhance the service life of the air

compressor effectively.

◆Negative pressure of printing platform controlled by

frequency-tranducer ensures adsorption precious for all kinds of material to

improve Y direction feeding accurate.

◆Introduction of industrial PLC control module controls each printing

step stable.

◆The solution of top quality towline reduces the motor cable fault to

zero.

◆LED lamp curing solution makes UV curing perfectly and completely.

◆Special control technology of second ink tank reduces the ink

leakage when

sudden blackout.

◆National patent press roller structure provides a solid foundation

for media

feeding.

◆Impressive national patent machine body.